How Structural Adhesives are Redefining Lightweight Design in Next-Gen Aerospace Manufacturing

Structural adhesives are revolutionizing aerospace by enabling lightweight, durable composite bonding, boosting fuel efficiency and design innovation.

NEWARK, DE, UNITED STATES, May 29, 2025 /EINPresswire.com/ -- 𝐈𝐧𝐭𝐫𝐨𝐝𝐮𝐜𝐭𝐢𝐨𝐧 𝐭𝐨 𝐒𝐭𝐫𝐮𝐜𝐭𝐮𝐫𝐚𝐥 𝐀𝐝𝐡𝐞𝐬𝐢𝐯𝐞𝐬 𝐢𝐧 𝐌𝐨𝐝𝐞𝐫𝐧 𝐄𝐧𝐠𝐢𝐧𝐞𝐞𝐫𝐢𝐧𝐠

The structural adhesives have evolved from being auxiliary bonding agents to critical components in advanced manufacturing processes. Traditionally used in construction and automotive applications, these adhesives are now seeing a transformative role in high-performance sectors like aerospace. Their ability to bond dissimilar materials, distribute stress uniformly, and reduce mechanical fastening requirements has placed them at the core of industrial bonding solutions. As demand grows for efficiency, safety, and sustainability in aviation, structural adhesives—particularly aerospace-grade adhesives—are becoming instrumental in redefining how aircraft are designed and assembled.

𝐋𝐞𝐚𝐫𝐧 𝐚𝐛𝐨𝐮𝐭 𝐭𝐡𝐞 𝐜𝐨𝐧𝐭𝐫𝐢𝐛𝐮𝐭𝐢𝐨𝐧 𝐨𝐟 𝐞𝐚𝐜𝐡 𝐬𝐞𝐠𝐦𝐞𝐧𝐭 𝐨𝐟 𝐭𝐡𝐞. 𝐑𝐞𝐚𝐝 𝐚 𝐒𝐚𝐦𝐩𝐥𝐞 𝐑𝐞𝐩𝐨𝐫𝐭: https://www.futuremarketinsights.com/reports/sample/rep-gb-2667

𝐓𝐡𝐞 𝐀𝐞𝐫𝐨𝐬𝐩𝐚𝐜𝐞 𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐲’𝐬 𝐒𝐡𝐢𝐟𝐭 𝐓𝐨𝐰𝐚𝐫𝐝𝐬 𝐋𝐢𝐠𝐡𝐭𝐰𝐞𝐢𝐠𝐡𝐭𝐢𝐧𝐠

In recent years, the aerospace sector has increasingly prioritized lightweight construction to reduce fuel consumption and lower carbon emissions. With jet fuel accounting for over 30% of airline operating costs, the incentive to shed every unnecessary kilogram is strong. This drive toward lightweighting is not just a design trend; it is a cost-saving and environmental imperative. While metals like aluminum and titanium once dominated aircraft structures, the industry is now heavily investing in composites such as carbon fiber-reinforced polymers (CFRPs), which offer excellent strength-to-weight ratios.

However, these materials introduce bonding challenges. Traditional fastening techniques like riveting or welding are less effective or even damaging when used with composites. This is where structural bonding agents step in. High-performance adhesives such as epoxy structural adhesives are uniquely suited to join these materials without compromising their mechanical integrity. These adhesives provide excellent load-bearing capabilities while maintaining flexibility and resistance to thermal expansion—a vital characteristic when dealing with materials subjected to extreme in-flight conditions.

𝐖𝐡𝐲 𝐒𝐭𝐫𝐮𝐜𝐭𝐮𝐫𝐚𝐥 𝐀𝐝𝐡𝐞𝐬𝐢𝐯𝐞𝐬 𝐚𝐫𝐞 𝐂𝐫𝐢𝐭𝐢𝐜𝐚𝐥 𝐟𝐨𝐫 𝐂𝐨𝐦𝐩𝐨𝐬𝐢𝐭𝐞 𝐁𝐨𝐧𝐝𝐢𝐧𝐠

The use of lightweight material adhesives in aerospace goes far beyond simple glue. Structural adhesives used in this domain are engineered for extreme strength, heat resistance, and durability. One of the most critical advantages they offer is uniform load distribution, which prevents stress concentrations that can lead to material fatigue or failure. This is particularly important in aerospace design, where even microscopic faults can have catastrophic outcomes.

Moreover, structural adhesives enable the bonding of complex geometries that would be difficult or impossible to assemble using mechanical fasteners. This flexibility allows engineers to explore innovative designs, such as single-shell fuselages or integrated wing-box structures, that contribute significantly to both weight reduction and aerodynamic efficiency. These advantages have positioned structural adhesives not only as an alternative but often as a superior solution to traditional methods in aircraft assembly.

𝐁𝐫𝐨𝐰𝐬𝐞 𝐭𝐡𝐞 𝐂𝐨𝐦𝐩𝐥𝐞𝐭𝐞 𝐑𝐞𝐩𝐨𝐫𝐭! https://www.futuremarketinsights.com/reports/structural-adhesives-market

𝐂𝐚𝐬𝐞 𝐒𝐭𝐮𝐝𝐢𝐞𝐬: 𝐀𝐝𝐡𝐞𝐬𝐢𝐯𝐞𝐬 𝐢𝐧 𝐀𝐜𝐭𝐢𝐨𝐧 𝐀𝐜𝐫𝐨𝐬𝐬 𝐀𝐢𝐫𝐜𝐫𝐚𝐟𝐭 𝐌𝐨𝐝𝐞𝐥𝐬

Boeing and Airbus, two of the largest aircraft manufacturers globally, have both integrated structural adhesives into their manufacturing lines. Boeing’s 787 Dreamliner, a landmark in modern aviation, is composed of nearly 50% composite materials by weight. This shift toward composites would not have been possible without the development and application of advanced structural adhesives. In the Dreamliner, epoxy structural adhesives are extensively used in the fuselage, wings, and tail sections to bond composite panels and components.

Similarly, Airbus utilizes structural bonding agents in its A350 XWB aircraft, where high-performance adhesives are applied in load-critical areas such as stringers and frames. These adhesives contribute to a lighter airframe without compromising on strength or safety. By reducing the reliance on rivets and bolts, Airbus has also managed to streamline assembly processes, lowering labor costs and increasing production speed.

These real-world implementations underline the growing reliance on structural adhesives in aerospace, beyond traditional uses. They highlight how these materials are key enablers of next-gen aircraft performance and manufacturability.

𝐈𝐧𝐧𝐨𝐯𝐚𝐭𝐢𝐨𝐧 𝐚𝐧𝐝 𝐅𝐮𝐭𝐮𝐫𝐞 𝐎𝐮𝐭𝐥𝐨𝐨𝐤 𝐢𝐧 𝐀𝐞𝐫𝐨𝐬𝐩𝐚𝐜𝐞-𝐆𝐫𝐚𝐝𝐞 𝐀𝐝𝐡𝐞𝐬𝐢𝐯𝐞𝐬

As the structural adhesive market evolves, R&D efforts are focusing on improving curing times, expanding temperature tolerance ranges, and enhancing compatibility with emerging substrates. Companies are developing hybrid adhesive systems that combine the strength of epoxy resins with the elasticity of polyurethane or acrylics, offering better performance under dynamic stress and thermal cycling.

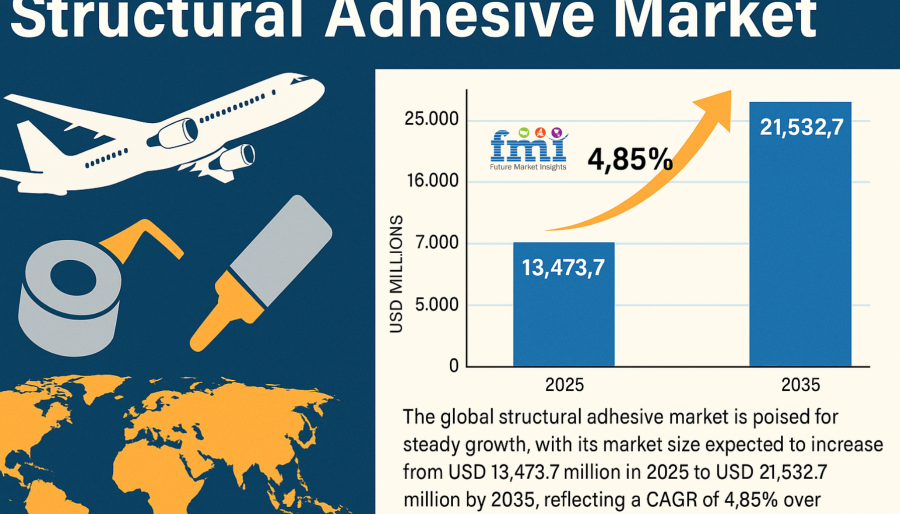

Moreover, regulatory frameworks and sustainability goals are pushing manufacturers to develop low-VOC (volatile organic compound) formulations and recyclable bonding solutions. The structural adhesive market analysis suggests a CAGR of around 4.85% between 2025 and 2035, driven largely by demand from aerospace and defense sectors. Growth is especially notable in North America and Europe, where investment in advanced air mobility (AAM) vehicles and electric aircraft is rising rapidly.

Another key trend is the integration of nanotechnology into adhesive formulations. The inclusion of nanofillers can significantly boost mechanical properties, thermal conductivity, and even electrical conductivity—traits that are becoming increasingly important in multifunctional aircraft components. Startups and established chemical manufacturers alike are filing patents for these new formulations, indicating a wave of innovation on the horizon.

𝐂𝐨𝐚𝐭𝐢𝐧𝐠𝐬, 𝐈𝐧𝐤𝐬, 𝐀𝐝𝐡𝐞𝐬𝐢𝐯𝐞𝐬 & 𝐒𝐞𝐚𝐥𝐚𝐧𝐭𝐬: https://www.futuremarketinsights.com/industry-analysis/coatings-inks-adhesives-and-sealants

𝐒𝐭𝐫𝐮𝐜𝐭𝐮𝐫𝐚𝐥 𝐀𝐝𝐡𝐞𝐬𝐢𝐯𝐞 𝐌𝐚𝐫𝐤𝐞𝐭 𝐒𝐞𝐠𝐦𝐞𝐧𝐭𝐚𝐭𝐢𝐨𝐧:

By Product Type:

- Epoxy-based Structural Adhesive

- One Component

- Two Component

- Acrylic-based Structural Adhesive

- Polyurethane-based Structural Adhesive

- Cyanoacrylates

- Others

By Application:

- Transportation Sector

- Automotive Sector

- Aerospace Sector

- Marine Sector

- Building & Construction Sector

- Energy Sector

- Others

By Region:

- North America

- Latin America

- Western Europe

- Eastern Europe

- South Asia and Pacific

- East Asia

- Middle East and Africa

𝐑𝐞𝐥𝐚𝐭𝐞𝐝 𝐑𝐞𝐩𝐨𝐫𝐭𝐬:

Aluminum Fluoride Market: https://www.futuremarketinsights.com/reports/aluminum-fluoride-market

Emission Control Catalyst Market: https://www.futuremarketinsights.com/reports/global-emission-control-catalyst-market

Coated Fabrics for Defense Market: https://www.futuremarketinsights.com/reports/coated-fabrics-defense-market

Industrial Pipe Insulation Materials Market: https://www.futuremarketinsights.com/reports/industrial-pipe-insulation-materials-market

Pharma Grade Sodium Bicarbonate Market: https://www.futuremarketinsights.com/reports/pharma-grade-sodium-bicarbonate-market

𝐀𝐛𝐨𝐮𝐭 𝐅𝐮𝐭𝐮𝐫𝐞 𝐌𝐚𝐫𝐤𝐞𝐭 𝐈𝐧𝐬𝐢𝐠𝐡𝐭𝐬 (𝐅𝐌𝐈)

Future Market Insights, Inc. (ESOMAR certified, recipient of the Stevie Award, and a member of the Greater New York Chamber of Commerce) offers profound insights into the driving factors that are boosting demand in the market. FMI stands as the leading global provider of market intelligence, advisory services, consulting, and events for the Packaging, Food and Beverage, Consumer Technology, Healthcare, Industrial, and Chemicals markets. With a vast team of over 400 analysts worldwide, FMI provides global, regional, and local expertise on diverse domains and industry trends across more than 110 countries.

Join us as we commemorate 10 years of delivering trusted market insights. Reflecting on a decade of achievements, we continue to lead with integrity, innovation, and expertise.

𝐂𝐨𝐧𝐭𝐚𝐜𝐭 𝐔𝐬:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-347-918-3531

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

LinkedIn| Twitter| Blogs | YouTube

Ankush Nikam

Future Market Insights Global & Consulting Pvt. Ltd.

+ +91 90966 84197

email us here

Visit us on social media:

LinkedIn

Facebook

YouTube

X

Other

Distribution channels: Chemical Industry

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release