DPM Mining Inc. Announces Creation of a SMART Mining System based on Canadian Patent No. 2853584 Issued Nov. 20th, 2020.

SMART is the only new mining method invented in the past 50 years. SMART replaces underground stopes and pillars with linked spreadsheets of 1,000t ore cells.

TORONTO, ONTARIO, CANADA, March 31, 2021 /EINPresswire.com/ -- The Gryba family research company, DPM Mining Inc. is pleased to announce that a key Canadian invention has been issued which allows creation of a new underground mining method that eliminates ore dilution, increases productivity 300% with improved safety. Australian, Mexico, US and other mining country patents have already been issued. Test mining at the Penoles Madero Mine confirmed the technology.

In essence, the Gryba invention coverts mining an orebody from a series of traditional stopes and pillars to a set of SMART spreadsheets. Zero base cost mining and milling a single 1,000 ton SMART cell, then the geological 3D block modelling program quickly calculates the NPV for the life of the mine. Enter new exploration, cost or production data, rerun the model, update management daily or monthly.

History: Canadian Mining Engineer Charles M. Gryba P.Eng. patented the DPM mining method in 1990. The current Canadian Patent explains how to install a continuous, steel reinforced concrete roof on top of concrete posts. The concrete roof ties together 10 DPM innovations developed over the past 30 years thus creating a modern SMART spreadsheet mining method.

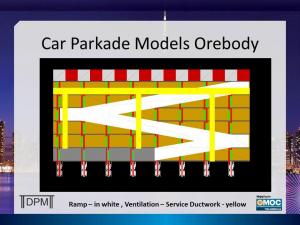

The simplest way to explain SMART is to visualize an orebody as a multilevel underground car parkade. The volume of ore between any 4 posts is a cell in a SMART spreadsheet, linking the spreadsheets together mines the entire orebody.

The original idea for SMART started with a 1983 Kidd Creek mine tour observation that the bottom of 30m wide, cemented rock filled (CRF) blasthole stope only arched 1 meter when mined out from below. Gryba with 50,000 hours of mine engineering, budgeting, operating and Noranda Research Centre experience was intrigued. Gryba had developed a strong belief that the industry must invent new mining methods to solve traditional mining problems.

The North American gold standard, “bulk mining method” since 1980 is VCR - blasthole stoping patented in the early 1970’s by CIL with Inco’s help. Block caving is 100 years old. Other traditional methods like cut and fill, room and pillar or shrinkage stoping, were invented by the Romans 2,000 years ago. None of the current mining methods are a good platform for mining innovation. NA mine development and stoping productivity has dropped 3% per year for the past 15 years – CEMI data.

Mining methods in 2021 are still plagued with high dilution, ongoing safety issues from rock falls, declining productivity and increasing costs. Kriged ore grade calculations, combined with complex planning and scheduling software, all add to the opaque nature of underground mining. SMART simplifies mining to a set of linked spreadsheets mined from the top down in 6m lifts, less development work plus quicker production reduces mining risks. As with any invention a few new terms are required.

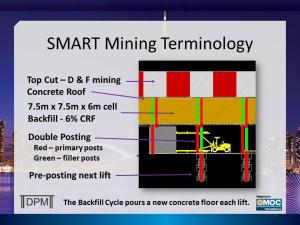

Image 1 shows a top cut (drift and fill mining), cell size, CRF, and double posting. The red and white colored drifts install the red precast concrete posts and pours the top concrete roof of the parkade. For hard ore, conventional mining equipment is used to excavate 15m wide x any length panels under the concrete roof. Roadheaders are used to mine soft ore. Filled primary panels act as temporary pillars allowing secondary panels to be mined. This gives 100% ore recovery in 1 pass of mining with individual SMART cells having 0% backfill plus close to 0% wall rock dilution.

Image 2 shows an underground car parkade with ramp access. The 1st lift post holes were drilled on a 7.5m x 7.5m grid to match the corners of the SMART cells as per the 3D geological block model. Once a 15m wide panel of ore is mined, a backfill cycle installs a new grid of posts, a concrete floor then CRF. Compression pads bolted to the bottom flange of all red posts allows the CRF and concrete roof to move when ore is mined from below. The critical problem was how to design the overall parkade to support 800 tons of the CRF per SMART cell vs the weight of 4 cars. The load on any red post could be as high as 3200t when it is the common corner post of 4 cells.

The post loading question was solved by Golder FLAC 3D computer mining an 8 cell x 8 cell x 5 lift orebody, round by round, using 10 types or strengths of backfill. A stiff, civil designed parkade failed at the post roof connection. Weak CRF or paste fill caused the roof to sag to far thus overloading the posts. Success - equip red posts with compression pads and use jammed 500Mpa CRF. Post loading reduces from 250tons to 150 tons as you mine down 3 lifts using standard 6% cement CRF. Heaviest post loading was always on the 1st SMART lift and post loads steady state by the 3rd lift.

A $5 million dollar test program was completed at the Penoles Madero Mine in Mexico to mine prove the SMART technology engineering design. Test mining a 15m wide panel was successful. Image 3 visually shows that the roof and posts stayed intact.

Test mining proved the overall SMART spreadsheet, as each cell is the same. SMART enhances just about every aspect of underground planning, economics, mining research and safety. The standardized SMART cell technology is directly transferable from mine to mine and is scalable from 1,000 to 15,000tpd @ 0% dilution. Concrete roofs monitored via load cells creates a safe work environment and allows modern innovations such as mechanical or remote mining, robotics etc. to be safely implemented.

Rather than keeping the SMART technology confidential, 10 EIN press releases will be issued to explain SMART to both the mining and financial markets. Stakeholders include exploration and mine geologists, production miners, retail investors, bankers, fund managers, mining analysts, mine operators, company directors, mine ministers and politicians. To quantify some of the 40+ SMART financial and technical improvements identified to date, 4 well known NA mines will be redesigned using the SMART platform.

Charles Gryba

DPM Mining Inc.

+1 416-801-6366

email us here

Visit us on social media:

LinkedIn

EIN Presswire does not exercise editorial control over third-party content provided, uploaded, published, or distributed by users of EIN Presswire. We are a distributor, not a publisher, of 3rd party content. Such content may contain the views, opinions, statements, offers, and other material of the respective users, suppliers, participants, or authors.